- Login

- Home

- MABA

- MABF

- What's New

- Events

- Resources

- Biosolids Advocacy Fund

- Contact Us

|

January 2024 - MABA Biosolids Spotlight Provided to MABA members by Bill Toffey, Effluential Synergies, LLC

Restoring the Solids Flow in Baltimore

“Solids are flowing as they should, at both plants.” This is a recent assessment of one contractor working for the Baltimore Department of Public Works at both Back River Wastewater Treatment Plant and Patapsco Wastewater Treatment Plant. Aging infrastructure, retiring public operators, and COVID had contributed to a crisis in solids flows, resulting in such headlines in mid-2022 as “New report outlines failures across 'nearly every level' of Back River Wastewater Plant.” Two years of focused effort by agencies, environmental consultants, and contractors, under watchful eyes of environmental groups and the media, have made good things happen for biosolids in Baltimore, and so the solids are flowing. The journey from “failures” to “flows” has been a great challenge for Baltimore, and Patapsco WWTP is a case example. Daily solids production had stopped completely in 2021. Lack of dewatering and drying operations caused Patapsco to become overwhelmed with solids, and plant effluent water quality was severely impacted. Under an emergency authorization, Baltimore contracted with the firm Hazen and Sawyer (Hazen) to provide daily on-site operational support, technical process control support, plant modeling, and other operations related tasks. Together with subcontractor Williams Environmental Services, Hazen assigned a small team of certified operators and engineers to get to work.

An aerial view of the Patapsco Wastewater Treatment Plant

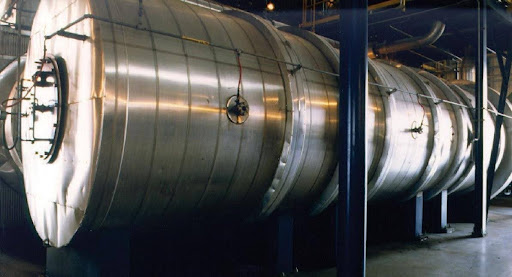

Restoring the sludge dryer (aSwiss-Combi direct drum dryer) was top priority. The dryer owner, Synagro, devised and permitted a temporary solids disposal outlet. Hazen and the City addressed issues of feed sludge quality and transfer. Solids production resumed with an agreement between Synagro and the City on a temporary processing plan. With implementation, the solids backlog eased. Hazen conducted a “root cause investigation,” leading to changes in sludge storage ahead of dewatering and drying. The recommended changes were successful, and Synagro was able to move away from the temporary plan. Dryers were fired back up in April 2023. Clearing out the excess solids inventory, maintaining daily solids production goals, and a renewed focus on communication and transparency between the City and Synagro have paid huge dividends. Patapsco WWTP was NPDES permit compliant for 2023, and all parties -- employees, consultants, and contractors, can be proud of Baltimore’s accomplishments.

Swiss Combi direct dryer drums at Patapsco

Baltimore DPW is a new member of the Mid Atlantic Biosolids Association, and Mahmudal Hasan, Ph.D., one of the agency’s new senior managers, has just begun his service on MABA’s Board of Trustees. But Baltimore’s leadership among the region’s biosolids programs is not new. Its iconic egg-shaped digesters at the Back River plant were among the earliest such installations in the country. Its adoption of public-private partnerships for production of Class A EQ biosolids products was also groundbreaking among large municipally owned utilities. Long term contracts in the early 1990s resulted in composting and pelletizing facilities, cutting edge at the time, and still in operation today.

Even as the imminent crises of 2021 to 2023 have subsided, significant projects are moving forward at the opening of 2024 to continue the solids handling improvements. Very significant is the major repair and upgrade of anaerobic digestion at the Back River plant. In addition to the visible egg digesters, solids are processed through in-ground pancake style anaerobic digesters, in an acid-gas sequence configuration, and the system has “wide spot” storage tanks to balance flows and for short term dewatered solids storage. These digesters and tanks are being cleaned and repaired, and pumps and gas collection systems replaced. Solids feed to digesters will be upgraded with new sludge thickeners. The cost of this large digester upgrade program is pegged at nearly $90 million. DPW has elected, as well, to keep in place its contractor-operated Class A EQ production capabilities. Veolia Water North America operates the Baltimore City Composting Facility, a hybrid system using an enclosed tunnel reactor and aerated curing piles. It receives approximately 35,000 tons of biosolids cake from Back River annually from which it produces about 50,000 cubic yards of OrGro biosolids compost. A stable commercial market for this compost has been developed by Veolia over the past three decades.

Veolia’s Baltimore City Composting Facility

MABA member Synagro, the owner of the Patapsco dryer described above, is also owner and operator of the dryer at Baltimore’s Back River WWTP. Originally selected and installed over 30 years ago, Synagro has managed to continue operating these unique, one-of-a-kind systems, in bundled full-service contracts that include dewatering, drying and marketing under the brand name Granulite. The Back River dryer, a Pelletech vertical multiple pan hot air dryer, is being repaired by Synagro, after an explosion in March 2023 put it out of service, but through it all Synagro has maintained drying and biosolids disposal services to the city. Feedstock to the Patapsco dryer is unstabilized sludge, a factor which contributes to vulnerabilities in operations, odor risks and product marketing, and a factor that will be addressed in future capital investments is solids processing.  Pelletech dryer at Back River

Improved operations at both Back River and Patapsco have restored treatment levels and solids flows to levels of regulatory compliance. DPW has rebuilt its workforce capabilities, with appointments of Dr. Hasan, biosolids manager and now Chief Technology Officer, and Mike Hallmen, manager of wastewater facilities, as examples of strong staffing. For the difficult period over the past two years, the state government had called upon Maryland Environmental Services along with Hazen, to assist DPW in expediting repair activity. Going forward, Jacobs, an engineering firm operating the Wilmington WRRF, has been contracted by Baltimore to handle solids treatment operations at Back River over the near term. A long-range master plan is under consideration, with a scope of capital reinvestment in solids handling of about $400 million, envisioned largely through public-private partnerships. An overarching initiative is a proposal to create a Baltimore Regional Water Authority, which would put drinking water and wastewater treatment for the entire County and some adjacent governments under one organizational and financial management umbrella. Just as it is true that it “takes a community to raise a child,” it takes a community of professionals with varied skills to manage biosolids, and Baltimore is one of the very strong examples. For more information, contact Mary Firestone at [email protected] or 845-901-7905.

|

The Egg Shaped Digesters at Back River WTP

The Egg Shaped Digesters at Back River WTP