|

September 2022 - MABA Member Spotlight featuring Denali

Biosolids compost: clean, green and in high demand

High-quality product from Denali’s Burlington County facility routinely sells out

Agitators keep materials well mixed at the composting facility. (courtesy of Denali)

Past a mountainous landfill and down a tree-lined road, Burlington County’s co-composting facility is largely quiet. But, for a first-time visitor, stepping inside the warehouse-size building is sensory overload: the air is steamy and rich with ammonia, there are few lights except on the massive machines churning a mix of woodchips and biosolids, and the backup sirens blare as front-end loaders add material to concrete bays.

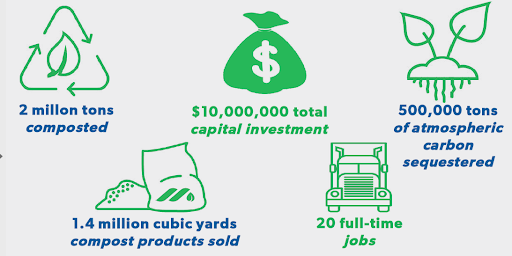

The result of this interplay between man, machine and decomposing microbes stands in a tall pile at an adjacent building: compost. Each year, the Burlington County facility creates 50,000 cubic yards of the stuff. That’s enough compost to cover a football field with a heap 20 feet high.

Despite the massive amount, Ryan Cerrato has no trouble selling it. Cerrato is the Vice President of Product Marketing at Denali, an organic waste management company. Denali’s motto is “waste should not be wasted.”

“We sell to large and small construction projects, specialty soil blenders, school and institutional grounds departments, and landscaping contractors — anywhere a soil amendment is needed,” Cerrato said. “The list is endless.”

The county has a reliable outlet for its biosolids — a term for material recovered in the treatment of wastewater— and the local government sees the resource beneficially used in its region. It’s a win-win for Burlington County.

A trommel screen sifts composted material at the Burlington County facility. (Courtesy of Denali)

The consistent, high-quality material made by Denali is a Class A product, under federal environmental regulations, meaning it meets stringent federal guidelines for safety. High temperatures in the composting process destroy whatever pathogens may have been in the biosolids And, because compost is a stable form of organic material, it locks up carbon and plant nutrients that slowly break down when compost is mixed with soil.

Compost processes like this one are one way in which cities and counties in New Jersey and the Mid-Atlantic region recycle their communities’ nutrients. Regulations in the 1970s and 80s brought an end to ocean dumping, which had been the primary means of biosolids disposal for the region. New Jersey went further and banned the placement of biosolids in landfills in 1985.

Meanwhile, people continued to flush their toilets, and local governments needed to find new outlets for their waste. Fortunately, science began to show composting was an effective way to turn biosolids into a safe, useful product. Governments began building enclosed composting facilities like Burlington County’s, where the compost is closely monitored.

“Because it contains biosolids, it is one of the most tested compost products in the world,” Cerrato said.

An added benefit to making compost indoors is a cleaner, more consistent material. There’s no debris blowing around to contaminate the product, and there are no rainy days or dry spells inside the building, Cerrato said. The product, therefore, is uncontaminated and is the same from year to year. Customers know they are purchasing the same quality compost every time, he said.

“It’s become a homerun with our customer base,” Cerrato said.

For additional information, contact Stefan Weaver, Senior Environmental Manager, Denali, at 717-990-9496 or [email protected].

|