- Login

- Home

- MABA

- MABF

- What's New

- Events

- Resources

- Biosolids Advocacy Fund

- Contact Us

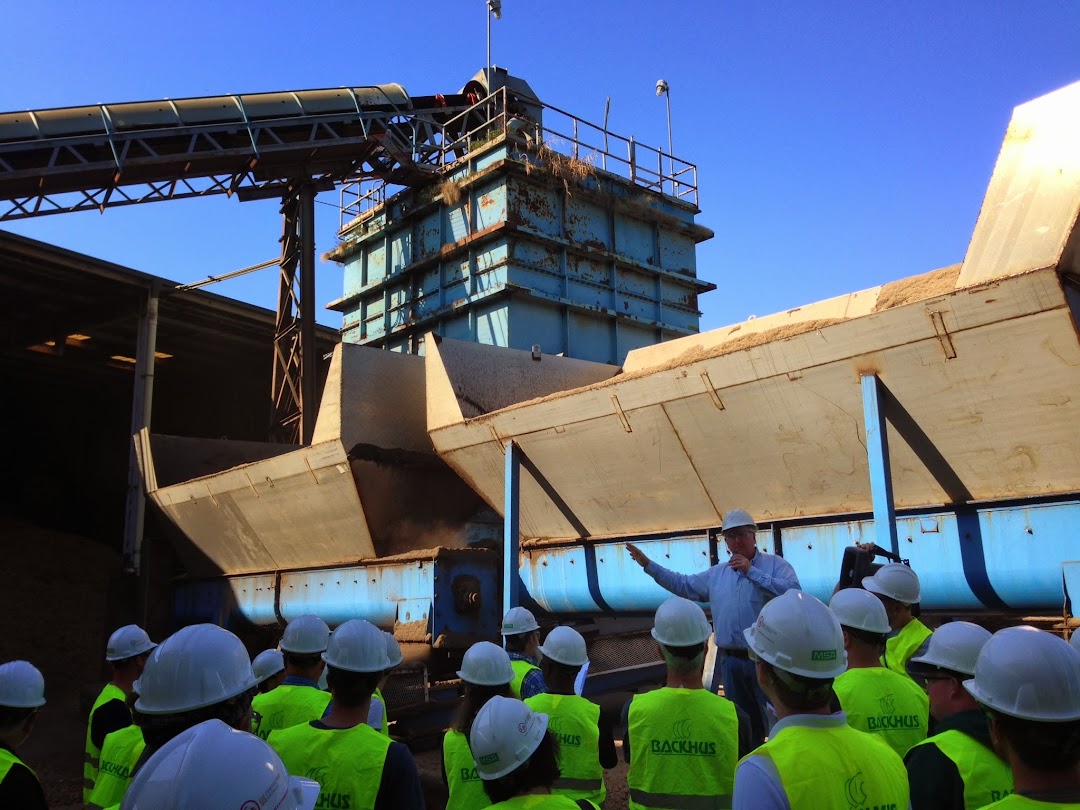

SPOTLIGHT on COMPOSTComposting is an enduring process for transforming biosolids into a Class A EQ product. Compost facilities in the mid-Atlantic region span a full array of sizes, technologies, and ownership models. The region has facilities located both at small water reclamation plants and at large treatment plants. It has windrow systems, enclosed static pile, and in-vessel agitated beds. Composting is done with various amendments -- purchased wood chips, yard debris, and organic matter recovered from solid waste. The region has various ownerships -- municipally-owned and operated composting, municipally-owned and contract-operated, and privately-owned merchant facilities. The common element to all of this variety is a product that is has a firm place in the landscape market for use in residential and commercial landscaping, as a component in soil blending, and as a specialty amendment for agriculture. Biosolids compost is a well-tested and well-accepted soil product. What is more, at least two more biosolids composting facilities are in permitting within the region. Below are several of the branded biosolids compost products made by MABA members McGill SoilBuilder Premium Compost For more than 30 years, McGill Environmental Systems has designed, built, and operated state-of-the-art indoor facilities for industrial-scale production of McGill SoilBuilder Premium Compost. It manufactures this premium compost product through the processing and recycling of non-hazardous, biodegradable by-products and residuals from municipal, industrial, and agribusiness sources. The McGill Regional Composting Facility at Waverly (McGill-Waverly) opened in 2008. It is in Sussex County, Virginia, near the town of Waverly. Its primary service area includes the coastal mid-Atlantic region. This encompasses the District of Columbia south through Richmond-Tidewater to northeastern North Carolina. McGill-Waverly accepts all types of biodegradable materials including food waste and compostable plastics. It is designed to receive and process source-separated wastes transported in roll-off containers, tractor-trailer rigs, and other commercial vehicles that can safely tip into the receiving bunker. Located on a former timber tract, the operation processes in both banked and encapsulated bays with aerated curing. Aerated curing eliminates the need for windrow turners at this facility. For more than 30 years, McGill Environmental Systems has designed, built, and operated state-of-the-art indoor facilities for industrial-scale production of McGill SoilBuilder Premium Compost. It manufactures this premium compost product through the processing and recycling of non-hazardous, biodegradable by-products and residuals from municipal, industrial, and agribusiness sources. The McGill Regional Composting Facility at Waverly (McGill-Waverly) opened in 2008. It is in Sussex County, Virginia, near the town of Waverly. Its primary service area includes the coastal mid-Atlantic region. This encompasses the District of Columbia south through Richmond-Tidewater to northeastern North Carolina. McGill-Waverly accepts all types of biodegradable materials including food waste and compostable plastics. It is designed to receive and process source-separated wastes transported in roll-off containers, tractor-trailer rigs, and other commercial vehicles that can safely tip into the receiving bunker. Located on a former timber tract, the operation processes in both banked and encapsulated bays with aerated curing. Aerated curing eliminates the need for windrow turners at this facility.For more information, contact Sean Fallon, Business Development Manager, [email protected], 919-406-4270. The Waverly facility is located at 5056 Beef Steak Rd, Waverly, VA 23890.

WeCare Compost WeCare Denali, a division of Denali Water Technologies, operates 24 composting facilities around the United States, two of which are county-owned biosolids composting plants. The Burlington Biosolids Composting Facility is a 300 ton per day capacity composting facility in Columbus, NJ, owned by Burlington County, but operated by WeCare Denali, serving about 20 agencies in the county and beyond. It is the largest biosolids facility in New Jersey under contract operations. The Rockland Green Co-Composting Facility, owned by the Rockland County Solid Waste Authority, recycles biosolids from wastewater plants in Rockland County, NY. At both plants, biosolids are mixed with clean wood waste and then composted in in-vessel agitated bed composting systems. The finished product is used on golf courses, flower gardens, and landscaping projects, and are also ingredients in topsoil This plant is adjacent to the Authority's Materials Recovery Facility and Transfer Station in Hillburn, NY. WeCare Denali markets a suite of WeCare Compost products under its WeCare Compost, Mulch, & Soil line. WeCare Denali, a division of Denali Water Technologies, operates 24 composting facilities around the United States, two of which are county-owned biosolids composting plants. The Burlington Biosolids Composting Facility is a 300 ton per day capacity composting facility in Columbus, NJ, owned by Burlington County, but operated by WeCare Denali, serving about 20 agencies in the county and beyond. It is the largest biosolids facility in New Jersey under contract operations. The Rockland Green Co-Composting Facility, owned by the Rockland County Solid Waste Authority, recycles biosolids from wastewater plants in Rockland County, NY. At both plants, biosolids are mixed with clean wood waste and then composted in in-vessel agitated bed composting systems. The finished product is used on golf courses, flower gardens, and landscaping projects, and are also ingredients in topsoil This plant is adjacent to the Authority's Materials Recovery Facility and Transfer Station in Hillburn, NY. WeCare Denali markets a suite of WeCare Compost products under its WeCare Compost, Mulch, & Soil line.For more information, contact national sales manager, Ryan J. Cerrato, [email protected], 315-575-4595. The Burlington facility address is 800 Coc-co Lane, PO Box 318, Columbus, NJ 08022. The Rockland facility is 1988420 Torne Valley Road, Hillburn, NY 10931. ORGRO High Organic Compost  ORGRO is a product of the Baltimore City Compost Facility, a facility owned and operated by Veolia, under contract with the city of Baltimore Department of Public Works. This facility, which was first built in 1984, processes a 45 dry ton per day portion of the anaerobically digested biosolids from the Back River Wastewater Treatment Plant, the balance made into a thermally dried product. The compost plant produces about 35,000 cubic yards of compost in through in vessel composting and extended curing. This facility is one of the original national examples of a public-private partnership, and one of the original programs for commercial marketing of biosolids to commercial landscapers. ORGRO is a product of the Baltimore City Compost Facility, a facility owned and operated by Veolia, under contract with the city of Baltimore Department of Public Works. This facility, which was first built in 1984, processes a 45 dry ton per day portion of the anaerobically digested biosolids from the Back River Wastewater Treatment Plant, the balance made into a thermally dried product. The compost plant produces about 35,000 cubic yards of compost in through in vessel composting and extended curing. This facility is one of the original national examples of a public-private partnership, and one of the original programs for commercial marketing of biosolids to commercial landscapers.For more information, contact Tom Fantom, project manager, [email protected], 410-354-1636. The facility address is 5800 Quarantine Road, Baltimore, MD, 21266.

Landscaper’s Advantage Landscaper’s Advantage is the product of the A&M Compost Facility, a large enclosed static pile composting plant owned and operated in Manheim, Pennsylvania by the J.P. Mascaro company. It is a merchant plant, accepting biosolids from a wide reach of plants in the mid-Atlantic. The facility is nearly 15 acres under roof. Its website offers a “virtual tour” slide deck describing the components of its operation and its environmental controls, which includes under one cover both aerated composting and biofiltration. A&M is managed by a registered professional engineer, Ryan Inch, PE, and a compost specialist, Mark Hubbard. Landscaper’s Advantage is the product of the A&M Compost Facility, a large enclosed static pile composting plant owned and operated in Manheim, Pennsylvania by the J.P. Mascaro company. It is a merchant plant, accepting biosolids from a wide reach of plants in the mid-Atlantic. The facility is nearly 15 acres under roof. Its website offers a “virtual tour” slide deck describing the components of its operation and its environmental controls, which includes under one cover both aerated composting and biofiltration. A&M is managed by a registered professional engineer, Ryan Inch, PE, and a compost specialist, Mark Hubbard. For more information, contact Matt Mascaro, [email protected], 267-228-5288. The facility is located at 2022 Mountain Rd, Manheim, PA 17545. earthlife Compost The Hawk Ridge Composting Facility, New England’s largest compost facility, is owned and operated by Casella Organics, a MABA Board member This facility uses an in-vessel tunnel system (the Gicom Tunnel) to compost a blend of biosolids with woodchips and sawdust, producing a screened compost with the tradename earthlIfe. Recently, Hawk Ridge reached the distinction of delivering its one-millionth cubic yard of compost. Its wholesale customers include golf courses, nurseries, garden centers, and athletic facilities. The Hawk Ridge Composting Facility, New England’s largest compost facility, is owned and operated by Casella Organics, a MABA Board member This facility uses an in-vessel tunnel system (the Gicom Tunnel) to compost a blend of biosolids with woodchips and sawdust, producing a screened compost with the tradename earthlIfe. Recently, Hawk Ridge reached the distinction of delivering its one-millionth cubic yard of compost. Its wholesale customers include golf courses, nurseries, garden centers, and athletic facilities. For more information, contact John Leslie, [email protected], 207-461-1000. The facility is located at 3 Reynolds Road, Unity, ME 04988.

|