- Login

- Home

- MABA

- MABF

- What's New

- Events

- Resources

- Biosolids Advocacy Fund

- Contact Us

|

July 2023 - MABA Biosolids Spotlight featuring Village of Endicott

Join us for a tour of the Village of Endicott plant Thursday, July 20 at the 2023 Summer Symposium!

For more information, contact Mary Firestone at [email protected] or 845-901-7905.

Working Forward in Biosolids Management

For almost 40 years the Village of Endicott Water Pollution Control Plant (WPCP) located in the Southern Tier of NYS has recycled biosolids. The WPCP has a 10 MGD design flow and serves about 50,000 people from the V. Endicott, T. Union and T. Vestal. The recycling of biosolids began in 1984 with a Taulman-Weiss In-Vessel system and shifted to the traditional windrow method in 2004 due to mechanical issues with the In-Vessel system. In an effort to reduce process time and costs while also continuing to recycle and produce Class A material, the WPCP added a Thermal Dryer. The thermal dryer reduces costs and time in the production of Class A material.

“The dryer allows the facility to eliminate the need for a carbon source,” said Philip Grayson, chief operator at Endicott, “Which is a significant cost in our compost operations.”' In addition, the Village had employed a full-time compost operator. Upon that employee’s retirement the position was eliminated through attrition, another significant cost savings benefit. Furthermore, the dryer process produces a Class A material in less than an hour versus the weeks and months needed for windrow composting. Endicott Belt Press Operation with dryer behind it

The Endicott WPCP is continuing to work with NYSDEC for the dried product to be an approved Class A material. The Village is exploring the traditional Thermal Drying Class A parameters, such as more than 90 percent solids requirement versus 75 percent solids if all material is stabilized municipal sludge. The Village recognizes time, energy and cost savings if a Class A product can be achieved at less than 90 percent solids. The Endicott WPCP is completing a Solids Handling Upgrade project that includes new anaerobic digestion membrane covers, mixing system, gas train, flare, septic receiving station, process water system and a thermal biosolids dryer.

The new equipment provides for increased reliability and access to repair and replacement parts. Grayson explained that the digester is performing better due to increased mixing, the gas train’s new safety devices and flare relocation bring the building into current building codes, the septic receiving station allows for the material to travel to one of two locations for treatment, a new process water pump and distribution lines, and the thermal dryer was the final piece to the Solids Handling Upgrade providing for a new way to treat and produce a beneficial product.

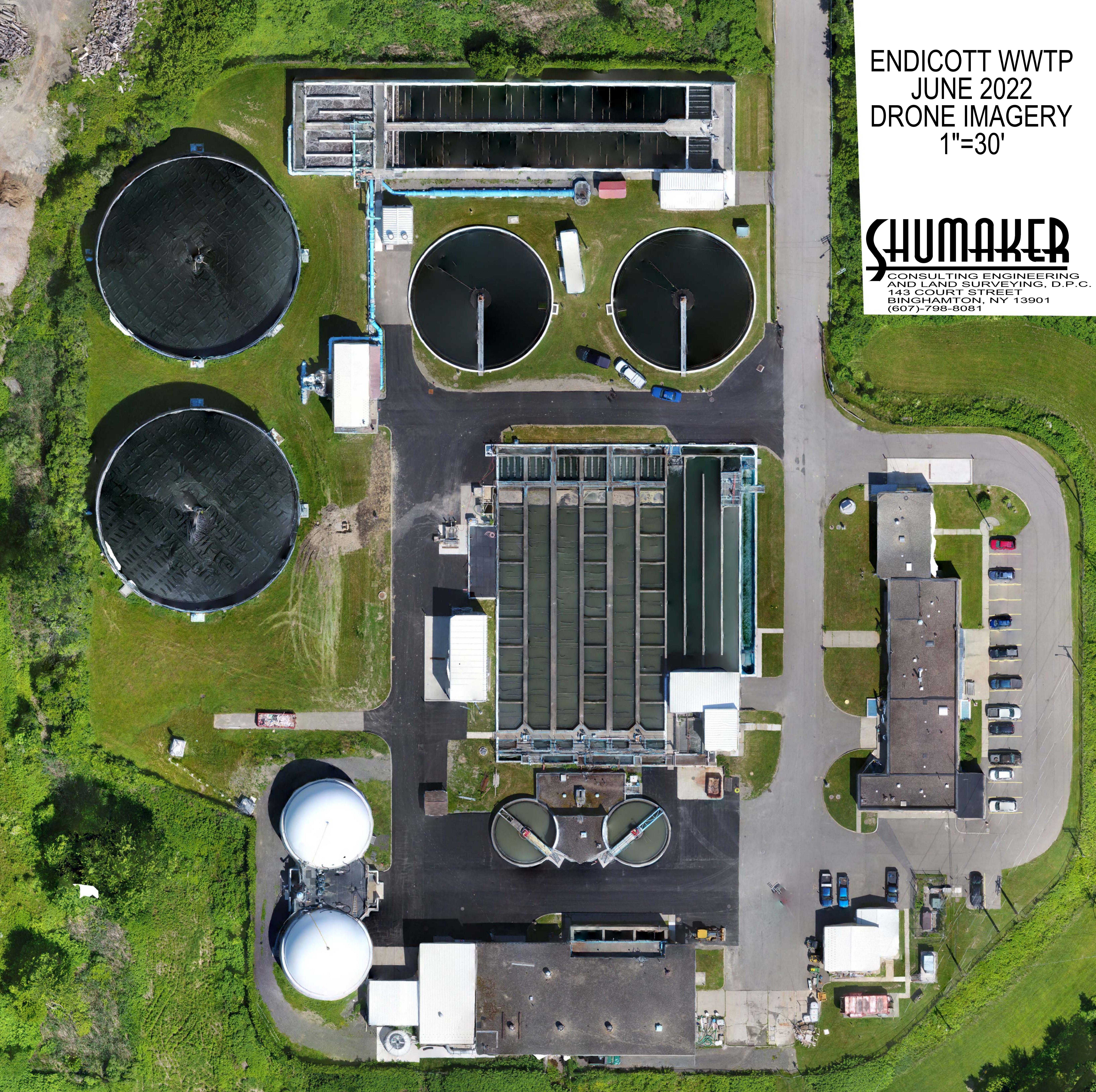

Endicott Plant drone image

“The upgrades give our system more flexibility, safety and reliability,” said Grayson, “This is achieved through providing options and redundancy within the system. There is now more than one path for our septic material (headworks or digester), multiple water sources on-campus (potable and non-potable) water and more than one way to achieve Class A material (windrow and thermal dryer). These upgrades together increase our ability to operate and achieve recyclable water and biosolids.” For additional information, contact Philip Grayson, Chief Operator, Wastewater, Village of Endicott at [email protected]. Join us for a tour of the Village of Endicott plant on Thursday, July 20 at the MABA 2023 Summer Symposium!

For more information, contact Mary Firestone at [email protected] or 845-901-7905.

|