|

February 2024 - MABA Biosolids Spotlight

Provided to MABA members by Bill Toffey, Effluential Synergies, LLC

Transforming Quakertown

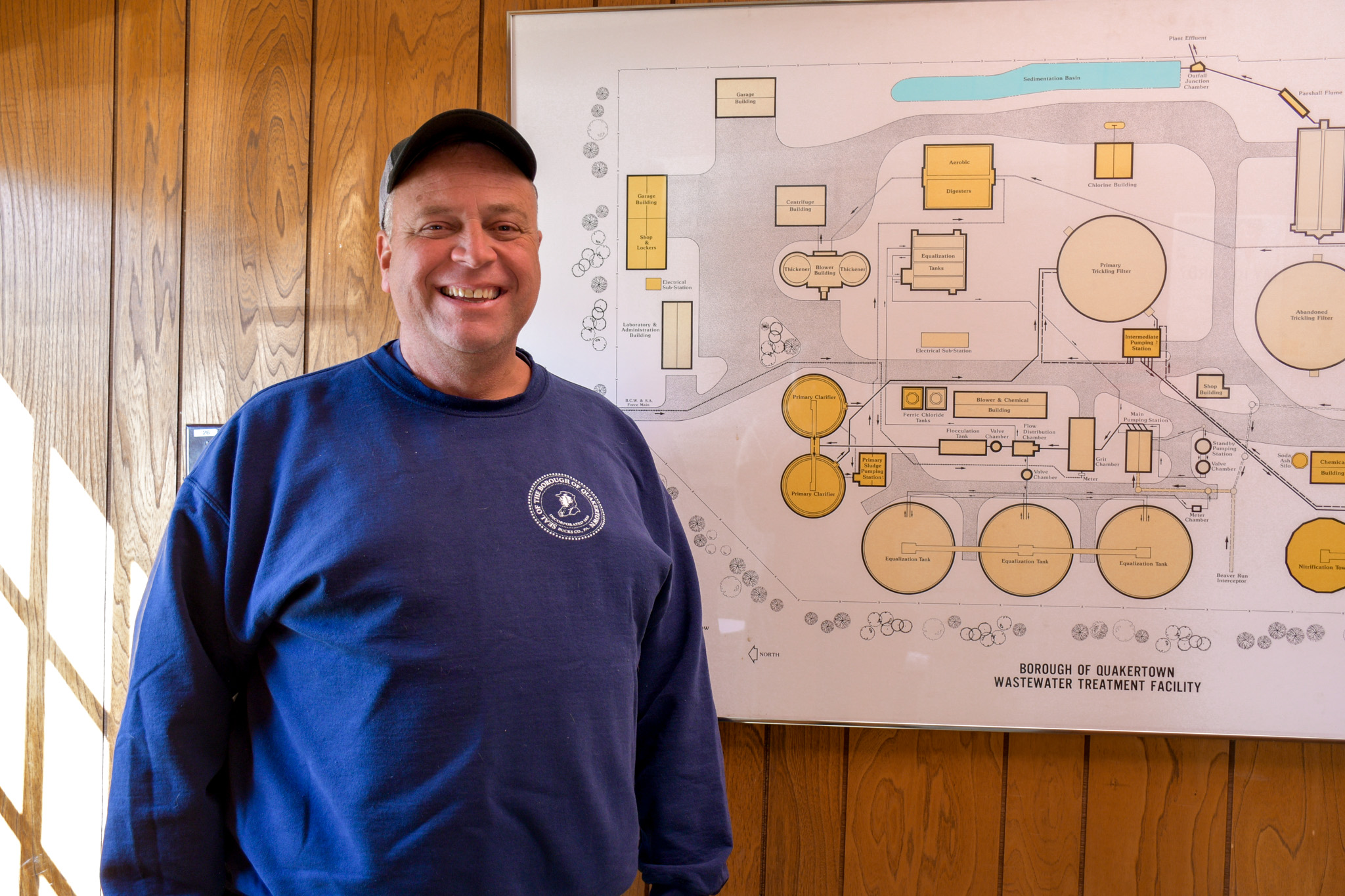

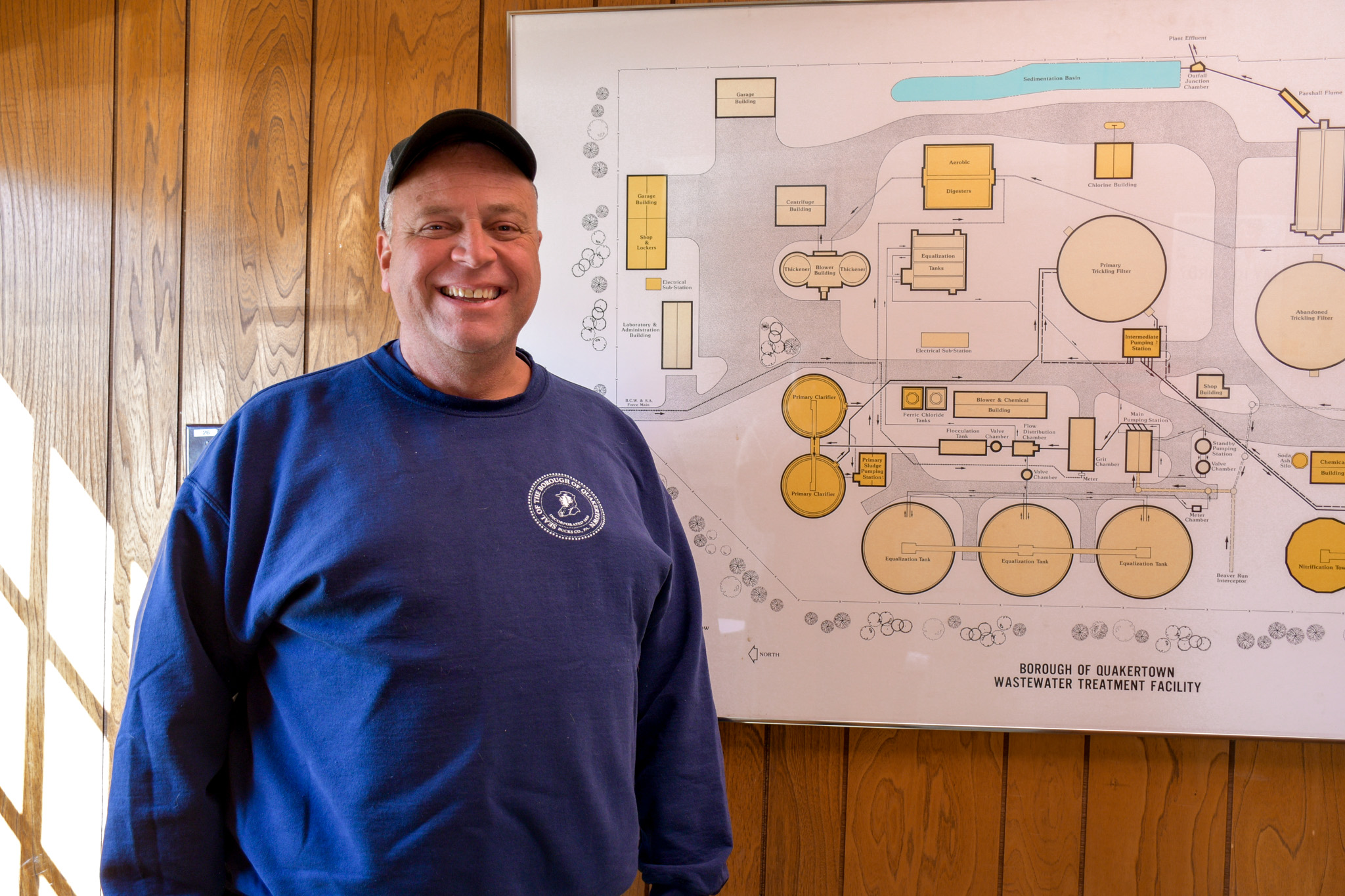

Dave “Butch” Erwin has big plans, very big plans! Erwin leads the Borough of Quakertown (PA) wastewater treatment plant, and he has seen his facility break ground early 2024 on implementing his “very big plans.”

Erwin’s vision takes in a wide view. He explains: “We stop landfill disposal of sludges, and we produce biosolids that we can recycle to local farms. We get green energy from the biogas which can run the plant. We can take in revenue from the trucked in food waste, which we hope one day will help us break even, or maybe even achieve reduced rates for the citizens of the borough.”

Dave “Butch” Erwin, Superintendent, Borough of Quakertown Sanitation Department

Erwin is motivated by both his love of the job and his love of the borough. He was raised in Quakertown, and today serves as the chief of its volunteer fire company. He was a 14-year-old when he first volunteered for the fire company, joining his father, mother and sister in this vital community service. At Kutztown University, he studied biology and took a job right out of college at the Orwigsburg wastewater plant. He was grateful for work that had a new challenge every day, and happy he was not stuck behind a desk. Upon graduation, he married his college love, and they lived for a while in Schuylkill County, raising two daughters, and, of course, also volunteering in the local fire company. His next career stop was at the Lehigh County Authority Industrial Pretreatment facility, an operation unusual for its large inflow of high strength organic waste. Dave realized that there must be a better use for the methane gas produced by anaerobic digestion and for opportunities for use of biogas and cogeneration. Hired 7 years ago as the superintendent of the Borough of Quakertown Wastewater Treatment Facility, Erwin has now put together all his ideas for a sustainable wastewater system, and he looks ahead to the next decade, as an unfolding vision becomes a capstone to a career in wastewater treatment and public service.

The Quakertown plant is on the outer edge of the Philadelphia metropolitan area, a fast-growing area for which the Quakertown plant’s 4 MGD capacity today is too small to accommodate expected growth in sewage flows. Upgrades underway today will take the plant to a 5 MGD capacity, but the “vision” is a plant of ultimately 7 MGD. Engineering details for the facility upgrade has been led by Mike Filmyer of BCM Engineers/ATC Group Services, LLC, in Plymouth Meeting, PA. Scarcely any component will remain untouched over the next several years.

Borough of Quakertown Wastewater Treatment Facility sign

In working with ATC, Erwin drew on a series of scenarios for use of “trucked-in” high-energy content liquid wastes. This big opportunity arises from the thirty or more sources of high strength organic wastes within affordable reach of Quakertown. As Erwin saw during his days at Lehigh County, these waste sources are potential customers for the kind of service Quakertown could provide with a smartly installed processing system.

The Quakertown plant has a unique opportunity in the borough’s ownership of its own electrical grid. The Borough experienced serious financial charges for its occasional high electricity demand, charges that could be avoided with the right kind of in-plant electricity generation. The borough buys electricity wholesale from the open market of the Northeast Grid, and the treatment plant stood ready to be a generator, supplying “green” electricity for its wastewater operations and managing its demand. The biogas from anaerobic digesters could produce the electricity for meeting plant needs and offsetting demand charges.

Quakertown also had an opportunity to increase the proportion of sludge solids it was taking to farmlands at affordable prices. Existing solids stabilization is through aerobic digesters, but resultant biosolids fail in winter to meet vector attraction standards for farmland use. This means a premium price is paid for landfill disposal costs in winter. This could be fixed with anaerobic digesters.

If these factors were not sufficient, the firm Anaergia, with its robust offering of anaerobic digestion and combined heat and power, showed Quakertown a path to a partnership that made ownership of electricity generating equipment practicable. Anaergia has a successful operation in the Mid Atlantic region. The kind of digester it has supplied to Camden County Municipal Utilities Authority (CCMUA) was a local reference facility for Quakertown. The operational talent it employs at the CCMUA in operating the CHP system and its related biogas equipment can be shared with Quakertown. The stars are aligned for this vision to be eminently do-able.

Image showing the site where the Combined Heat and Power (CHP) will be located. The company removed an abandoned tank and is currently working to back fill the area with recycled concrete. Image showing the site where the Combined Heat and Power (CHP) will be located. The company removed an abandoned tank and is currently working to back fill the area with recycled concrete.

Erwin’s plan for enhancing the sustainability of his operations includes a focus on biosolids recycling. The Borough has an uncommon arrangement by which it uses its own tractor trailers and employees to deliver biosolids to local farmers. In 2023 Erwin delivered borough biosolids to three nearby farms. At present, Denali is contracted to provide field application services, though this service is in the process of being rebid as this article is in preparation.

Denali’s local land manager for the past several years, Ryan Cherwinski, counts Quakertown among Denali’s best partners. Cherwinski explains that the agency’s aerobically-digested cake product is consistently low in odors and easily stored and spread, and the plant staff is super at communications and coordination. Cherwinski believes that the future for Quakertown could well be year-round recycling, if the opportunity for on-farm storage is developed. With the buildout of the new facility, Quakertown foresees production of 30 tons per day of cake, at 25 percent total solids.

Erwin already has the firm Material Matters drafting paperwork for the future biosolids production. Natalie Switala, senior wastewater specialist, is handling solid waste permits for disposal and use of the new biosolids products. Over the past several years, Pennsylvania DEP has floated the proposal to require those municipal plants accepting trucked-in high strength organics to obtain their own utilization permits, outside the current General Permit 08 for Non-Exceptional Quality Biosolids. Switala has these permit applications underway.

Ground has broken for the new biosolids facility. Stormwater basins are being relocated, and the site of the new generators has been cleared for pouring the building foundation. The public private partnership with Anaergia calls for two anaerobic digesters, each about one-half million gallons, using the Anaergia Omnivore design that handles “high solids” liquid sludge feed, meaning it accepts a liquid feed of 12 percent solids. Existing aerobic digester tanks will be repurposed as equalization tanks for digester feed. These tanks will accept about 14k gallons of thickened sludges from the primary and secondary tanks at the plant itself, but also will take in deliveries of 35k gallons of food waste, of fats, oils and grease (FOG) and of sludges from nearby small wastewater plants. These tanks will be kept well blended and will provide for consistent thickened liquid feed to the digesters. Half of the organic loading to the digesters is expected to be from these outside sources.

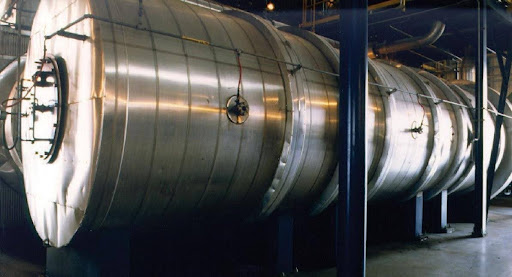

Image is of Quakertown 1920 sludge holding tanks. These will be reconditioned and updated to be sludge holding tanks.

The Quakertown plant has a state-certified lab on site. This lab will be used to check each load delivered for conformance to the characteristics approved in advance by Quakertown. All sources will require pre-authorization and chemical characterization.

The Quakertown plant is in a sweet spot when it comes to its electricity supply and generation. Quakertown owns the electrical grid within the borough limits. Two internal combustion engines, each 800 kW in size, will be fueled with the digester gas, after gas clean up to remove water, sulfur, and siloxanes. The ICE will work as combined heat and power (CHP) energy generators to provide 800 kWe of heat for the digesters and building and deliver a steady 1.0 mWe of baseload electricity for plant operations, with occasional surplus electricity fed to the borough’s grid. The engines will be fueled only with digester gas, as the premium cost of developing peak shaving using larger dual fuel generators did not show a return on investment.

Two new digestors will be installed in this location. The current digestors hold 800,000 gallons and the new ones will be able to hold 600,000 gallon each, almost doubling our capacity.

Anaergia has been important for driving the Quakertown project. Its staff conducted a survey of the market in this part of southeastern Pennsylvania for the processing of high strength organic waste. This included grease trap haulers, food processors, and WWTPs, and checking on current tipping prices with facilities elsewhere in the metropolitan area. Avi Dalfen is Anaergia’s process engineer, arranging the digester, biogas and CHP systems, which will include a double membrane gas storage roof to allow for steady biogas feed to the generators. Anaergia has supplied the digesters and CHP units for Quakertown’s purchase and ensures integration of the several units. After installation, Anaergia will provide maintenance services.

Subsequent to the installation of the digesters and the CHP, Quakertown will rebuild its dewatering facility. The existing centrifuges will be replaced, and new systems will include conveyance of biosolids cake to waiting trucks. This will replace the current attention operators need to give to cake loading to the trucks. The centrifuges will be operated two shifts daily, seven days a week, which may require the Borough to add one trailer to its current fleet of three that provide cake storage through the weekend.

Patience is what our entire biosolids community needs today. A transformation is underway at Quakertown, and Erwin believes that in two years the major components of his vision will be operational. Perhaps the Mid-Atlantic Biosolids Association can get dibs in for a conference with a plant tour in Quakertown the Summer of 2026, just ahead of the United States Semiquincentennial. Now, that is a vision worth having!

|

The Egg Shaped Digesters at Back River WTP

The Egg Shaped Digesters at Back River WTP