|

May 2023 - MABA Biosolids Spotlight

featuring Passaic Valley Sewerage Commission (PVSC)

Passaic Valley Sewerage Commission moves forward

with Biosolids Management Master Plan

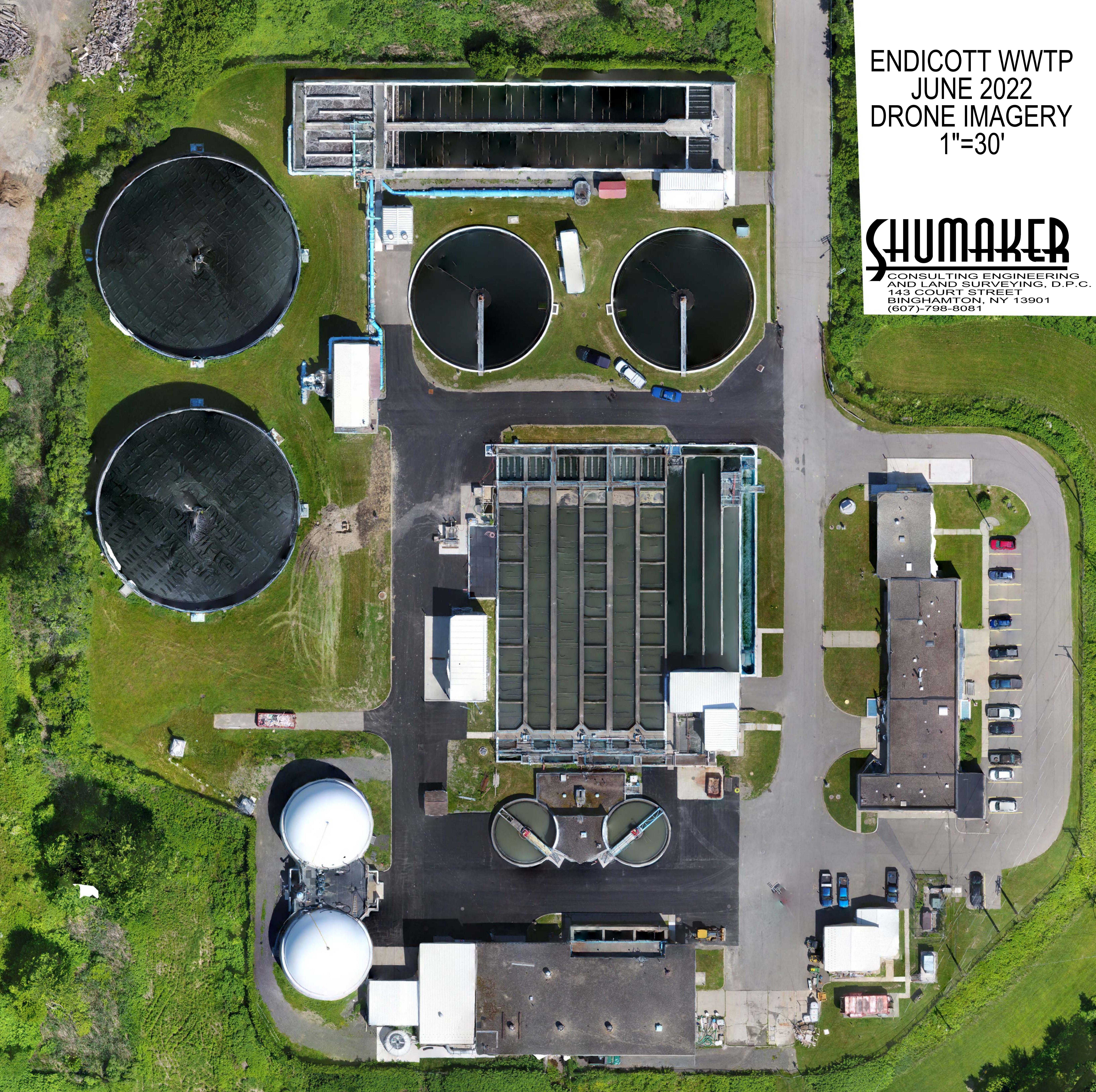

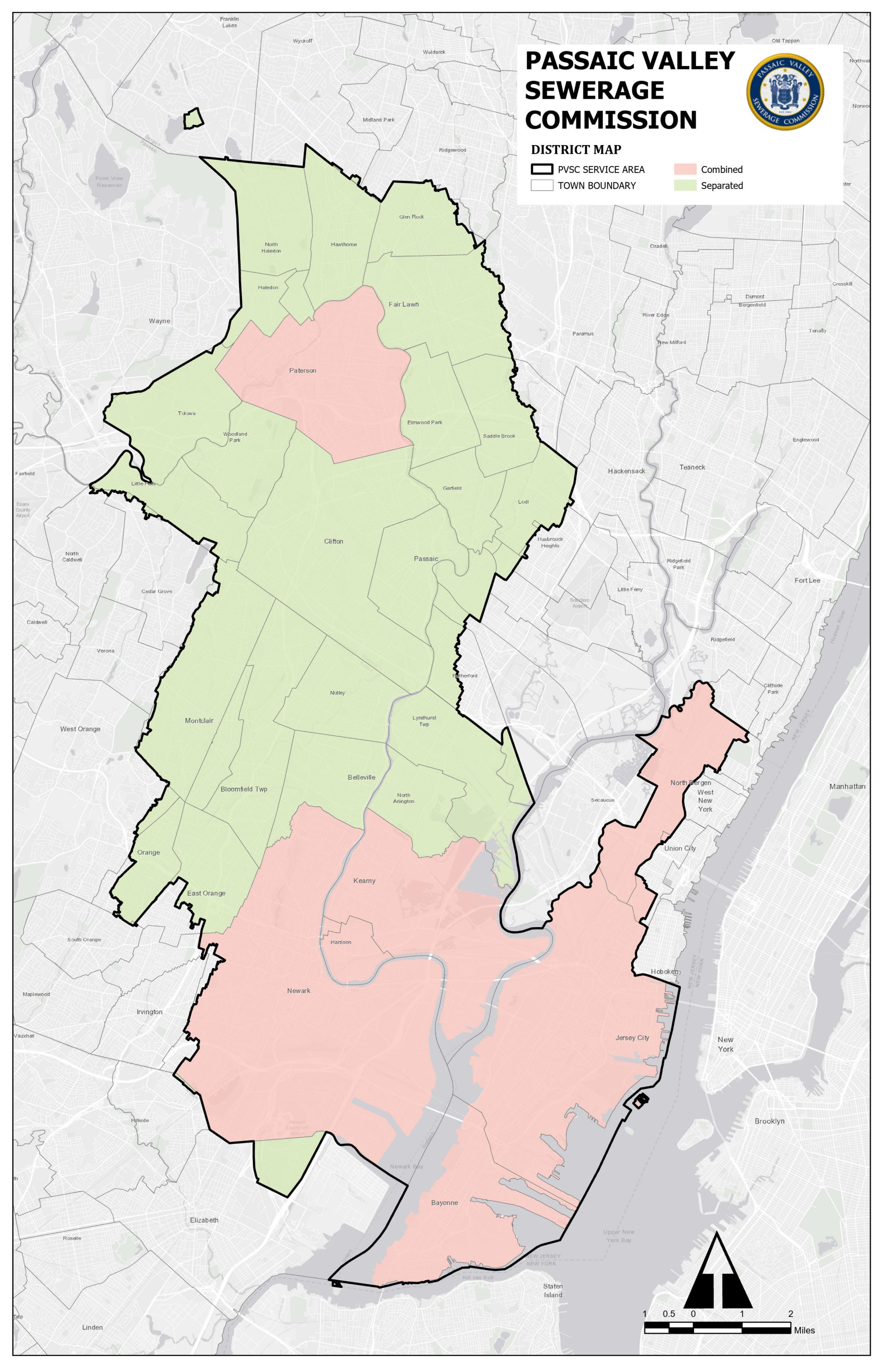

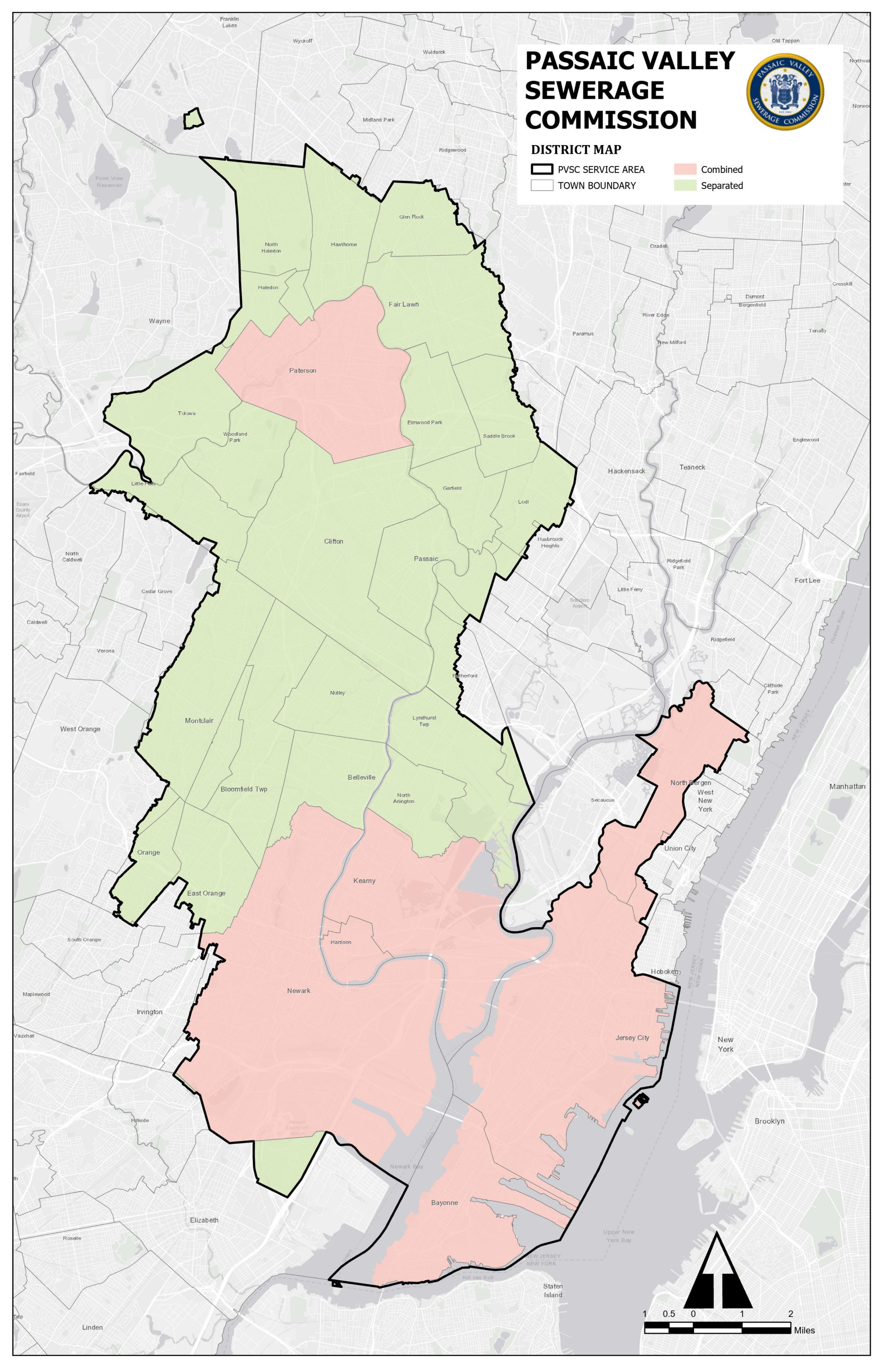

The Passaic Valley Sewerage Commission (PVSC), established in 1902, began operation of the Newark Bay Treatment Plant in 1924 as a means to alleviate pollution in the Passaic River and its tributaries. Major expansions, upgrades and renovations throughout the twentieth century have made the PVSC one of the largest wastewater treatment plants in the United States.

Since 1902, the PVSC has expanded its mission to enhance the viability, and environmental health and security of the 1.5 million residents in the 48 municipalities of Bergen, Essex, Hudson, Union and Passaic Counties of the Passaic Valley Service District. PVSC operates and maintains the infrastructure of a region that includes the Newark Bay Treatment Plant and its 22-mile interceptor sewer line to enable the processing of over 300 Million gallons of wastewater every day.

And now PVSC moves forward into a second century of service to its ratepayers with an aggressive plan to control costs and identify alternative funding sources for necessary infrastructure maintenance, automation, and upgrades, while providing innovative, environmentally sound and cost effective wastewater treatment.

The scope of work consists of development of a Biosolids Management Master Plan for PVSC that guides future upgrades to meet potential regulatory drivers and needs of the Utility for the next 10-20 years. The project was awarded to Arcadis, CDM Smith and HDR in April 2022.

The sludge management program at PVSC consists of thickening, thermal sludge conditioning (Zimpro), dewatering, and off-site disposal of the dewatered solids. Zimpro’s wet air oxidation process consists of an aqueous phase oxidation of organic materials that is accomplished at elevated temperatures and pressures.

“The wet-air oxidation process (Zimpro) went into operation in the early 80’s,” says Patricia Lopes, Director Of Process Control Engineering and Regulatory Compliance for PVSC, “We must be the only operating Zimpro treatment in United States for municipal sludge biosolids management – particularly at this size. And with an estimated 25 year life, and ours being over 40 years old, we were looking for new options.”

Lopes explains that among the main reasons for the Biosolids Master Management Plan (BMMP) was the aging equipment, which although it requires high energy and trained and qualified maintenance personnel, it remains very resilient. PVSC’s operational, maintenance and in-house fabrication capabilities have played a large part in the longevity of the Wet-Air Oxidation process equipment.

Lopes shares that the current treatment process is a very forgiving one, and allows PVSC to continue their liquid waste program while generating a Class A biosolids; 50-55% total solids product, with very little use of chemicals. In the end, Lopes says the new regulations, energy costs and the age of the equipment truly drove the interest in replacement or upgrades to the system.

Regulatory permit requirements will guide the Biosolids Management Master Plan, which Lopes says is currently in a conceptual design phase. Lopes says the project work is being shared with both Arcadis, CDM Smith and HDR to afford a more holistic approach to the necessary design and work needed for PVSC.

Lopes estimates that the project development will be completed within the next year or so, and PVSC expects that Arcadis, CDM Smith and HDR will be recommending several technologies at that time. Lopes expects that the project may take approximately 10-15 years to complete, and she emphasizes the importance of the project and PVSC’s work for the region.

“We receive about 300 trucks daily - plus 48 municipalities and barges from Bergen County Utilities Authority and New York City,” says Lopes, “The impact during Hurricane Sandy further amplified that issues at the Passaic Valley Sewerage Treatment plant become regional and statewide issues. What we’re doing is not just for us, but rather an impact that can be felt statewide.”

For additional information, contact Patricia Lopes, Director Of Process Control Engineering and Regulatory Compliance, at [email protected].

|